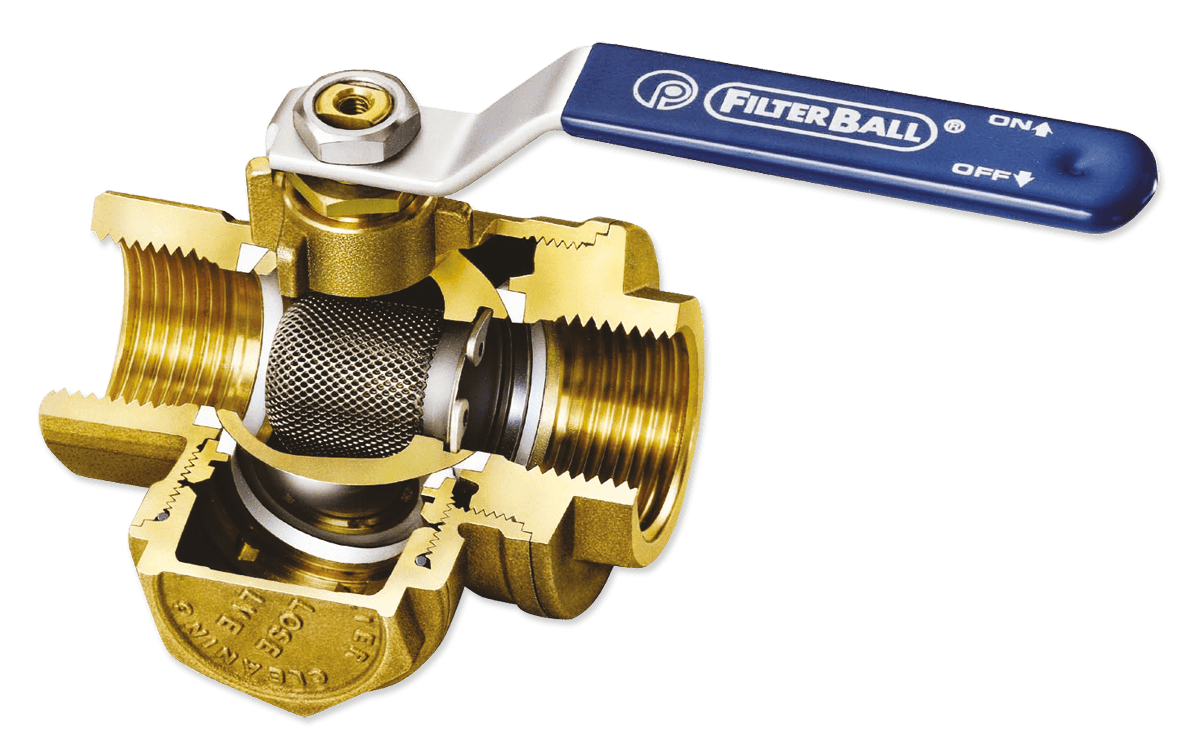

One FilterBall® = Two ball valves + One strainer!

Pettinaroli

3-in-1 valve rejuvenates the manufacturing of your heat pump, biogas plant or water/heat installation

The smart FilterBall® valve is a 3-in-1 product that integrates two ball valves and one strainer in one valve. This simplifies the traditional installation, which normally requires two ball valves and one Y strainer.

BOTTOM LINE: YOU REDUCE BOTH YOUR PRODUCTION COSTS AND THE PRODUCTION TIME

Five benefits of using Filterball® in your heat pump, biogas plant or water/heat installation:

1. Save production costs

The purchase price of one Filterball ® is approx. 20% lower than the price of two valves + one Y strainer. Furthermore, the installation time is one third as you only have to make two joints instead of six joints. Get a specific calculation of your savings

2. Double the flow – compared with a standard Y strainer (assuming same load losses)

Example: FilterBall®1”: KV (1 bar) = 14.5 m³/h. Y STRAINER 1”: KV (1 bar) = 7.0 m³/h. See measure drop diagrams

Get a calculation of how much your flow increases with FilterBall®

3. Save energy

It requires much less energy (pump pressure) to push liquid through the Filterball® than through a Y strainer.

4. Reduce risk of leakage

Simply due to two joints rather than six joints.

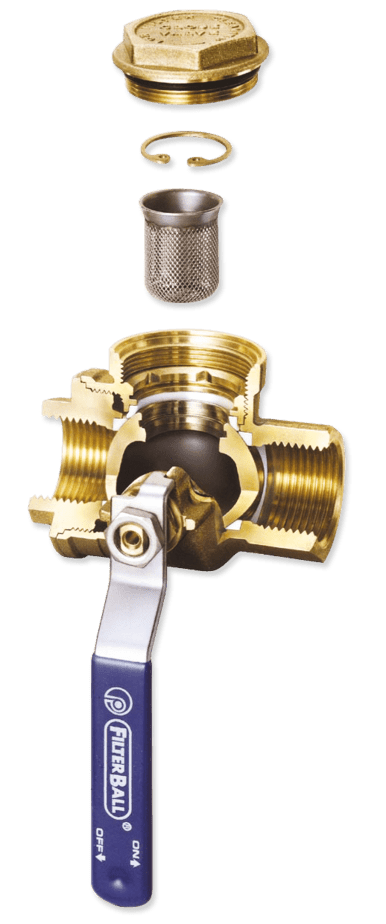

5. Easy to inspect, clean or change the filter

It can be done without taking the pressure off the installation. You can get the filter in three different mesh sizes. See how easy the filter is cleaned

Get a calculation of your flow increase

Pettinaroli A/S offers you specific calculations of how much your flow increases with Filterball®. Just fill in the form and send it.

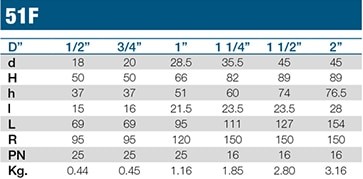

TECHNICAL SPECIFICATIONS

- Ball valve with integral strainer.

- Made of corrosion resistant brass alloy CW602N (also CW511L 0,1), threaded ends.

- Stem with triple safety (2-O-Rings, PTFE ring), fitted from inside to prevent tampering extraction or bursting.

- Double tightening in the joint between body and end-connection.

- Stuffing box movable.

- Solid spheres are made using diamond tools and chromium plated to the required thickness.

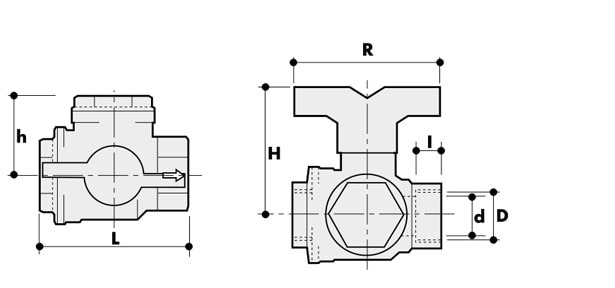

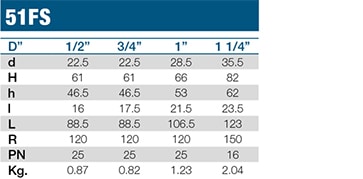

- Reversible handle. ( Art. 051F )

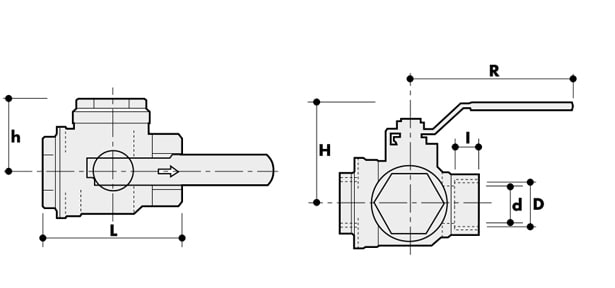

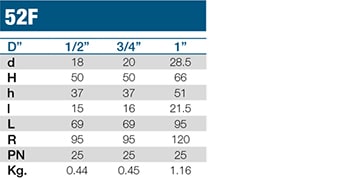

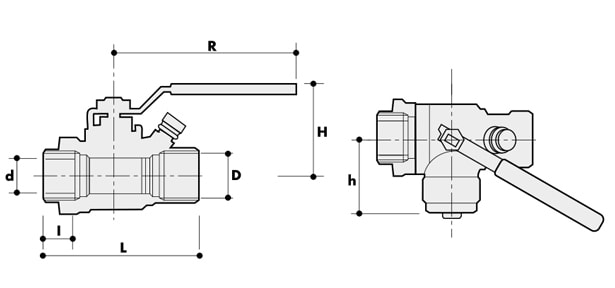

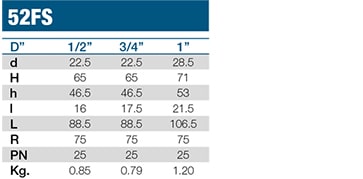

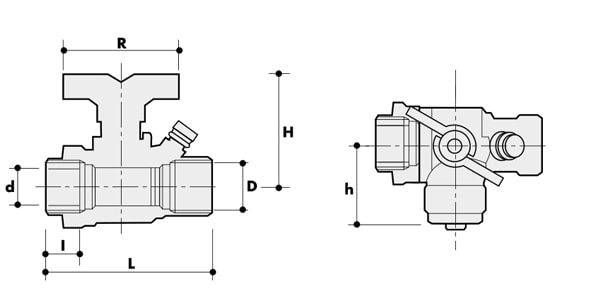

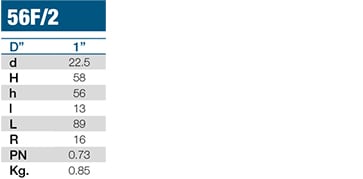

- Automatic cleaning device, with back flush feature. ( Art. 52F – 56F/2 )

Filterball® – available products

About

Pettinaroli Group is leading manufacturer in the HVAC industry, renowned for quality, integrity, and innovation. Our products range from valve distribution to the design and supply of complex bespoke manifolds.

Two Pettinaroli brothers established the company in 1938 in Italy. Here the products are still manufactured and distributed via the group’s companies in the US, France, Switzerland, UK, and Denmark. Quality has always been a core value for us. Hence, we are ISO 9001 certified on our quality efforts. Furthermore, every single valve is tested before leaving the factory.

From our Danish warehouse, Pettinaroli A/S delivers products to 20 countries in Northern, Central and Eastern Europe.

Your contact at Pettinaroli A/S

ANDRÉ BEKKE

Export manager, Europe

Ph. +45 2121 7340